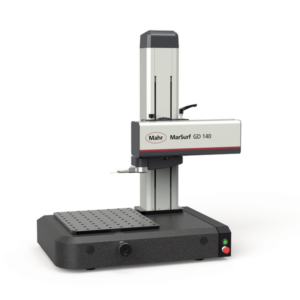

Mahr MarSurf CM Mobile

Maximum flexibility

Mobile 3D surface measuring instrument for use in the production environment. Ability to measure and analyze areas accurately – contactless, independent of material, and fast.

Description

Typical measuring tasks

- Roughness measurements as per ISO 4287 & ISO 13565 / ISO 25178

- Topography measurements (including volume, wear, tribology)

- Contour and form (2D, 3D)

- Pore, particle analysis

- Defect detection

Mobility

The MarSurf CM mobile was developed to complete measurements on large objects and samples that are difficult to move, such as rollers, tools, etc. It is thus easy to transport and is ready to use on site in just a few minutes.

Maximum data quality

One of our most important criteria, which equates to excellent precision, accuracy, repeatability, reproducibility and documentation to ensure traceability and audit ability. Our greatest service for the customer is to provide a quantitative measuring value that can be implemented reliably in the engineering, product, process design and quality control areas.

Correct, reproducible measurement

Your measuring data is recorded reliably, can be replicated, and guarantees the highest quality of raw data and profile accuracy.

Robust design

Patented technology enables reliable measuring data to be recorded even in the event of adverse conditions outside the measuring room.

Intuitive handling

Simple, user-guided interface with automatic modes for all significant measuring parameters, including use of measurement protocols for known surfaces.

Reviews

There are no reviews yet.