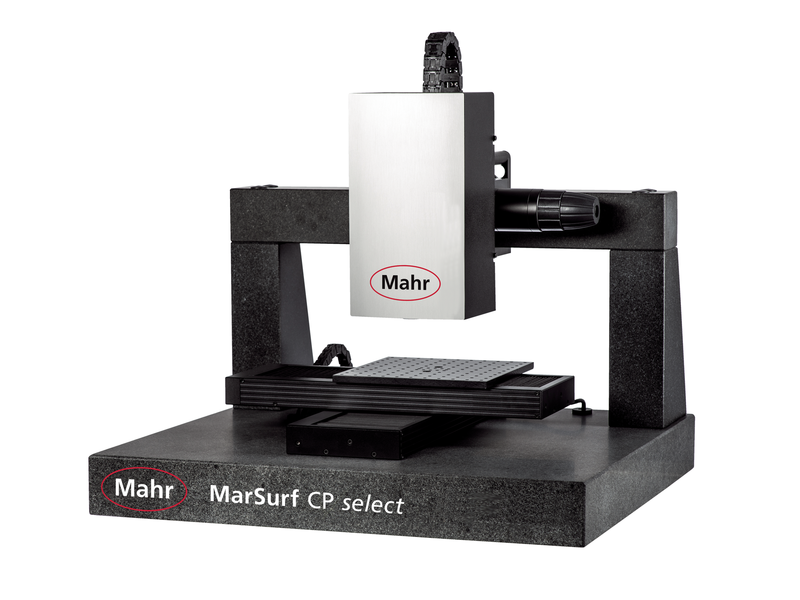

Mahr MarSurf CP/CL Select

Established optical profilometry for QA

Optical profilometers with which you can complete two- and three-dimensional measurement and analysis of surfaces – contactless, independent of material, and fast.

Description

Flexible solution for quality control

The MarSurf CP select stands out for extremely fast recording of large measuring surfaces while also ensuring high measuring precision. Thanks to its modular design, the measuring system can be adjusted to various measuring tasks and individual automation, measuring convenience, and accuracy requirements.

Typical measuring tasks

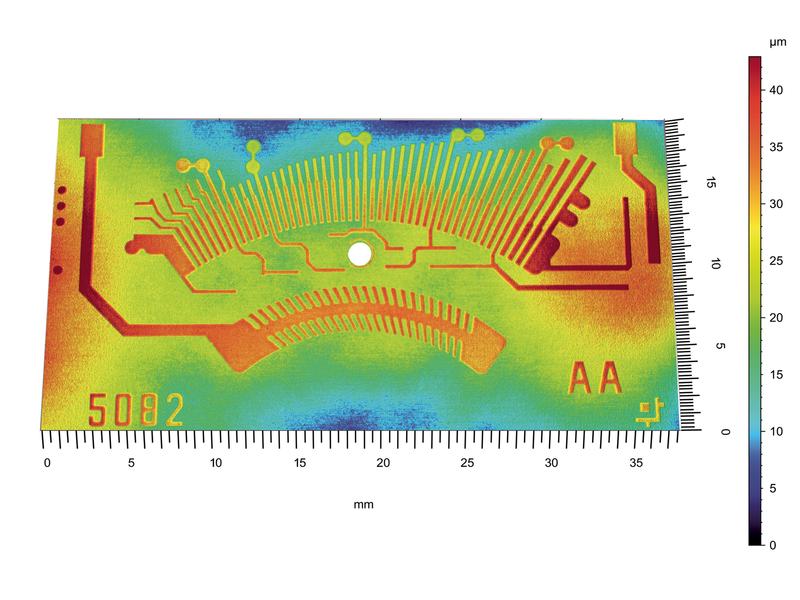

- Roughness measurements as per ISO 4287 & ISO 13565 / ISO 25178

- Topography measurements (including volume, wear, tribology)

- Layer thickness measurement

- Contour and form (2D, 3D)

- Macro and micro geometries

- Determination of flatness and coplanarity

Maximum data quality

One of our most important criteria, which equates to excellent precision, accuracy, reproducibility and documentation to ensure traceability and auditability. Our greatest service for the customer is to provide a quantitative measuring value that can be implemented reliably in the engineering, product, process design and quality control areas etc.

Correct, reproducible measurement

Your measuring data is recorded reliably, can be replicated, and guarantees the highest quality of raw data and profile accuracy.

Large measuring range

Complete freedom of portal design and flexible component selection from a module building set.

Automated processes

Fully automated, database-based pallet measurements with automated measuring and evaluation sequence (user-dependent one click solution).

Reviews

There are no reviews yet.